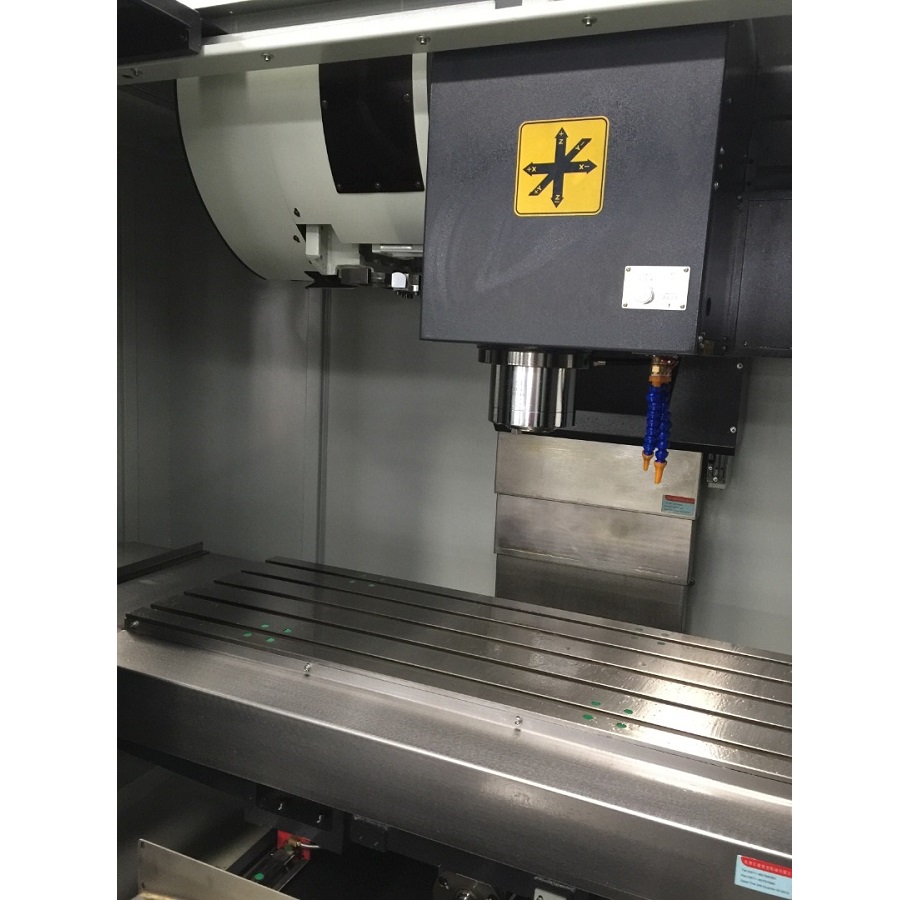

Semco Vertical CNC Machining Centres

Semco Vertical CNC Machining Centres – Built for Performance and Reliability

At Semco, we offer an extensive range of vertical CNC machining centres, backed by decades of hands-on experience and a deep understanding of modern production techniques. Whether you’re a high-volume manufacturer or a precision prototyping workshop, we have a solution to fit your needs, size constraints, and budget.

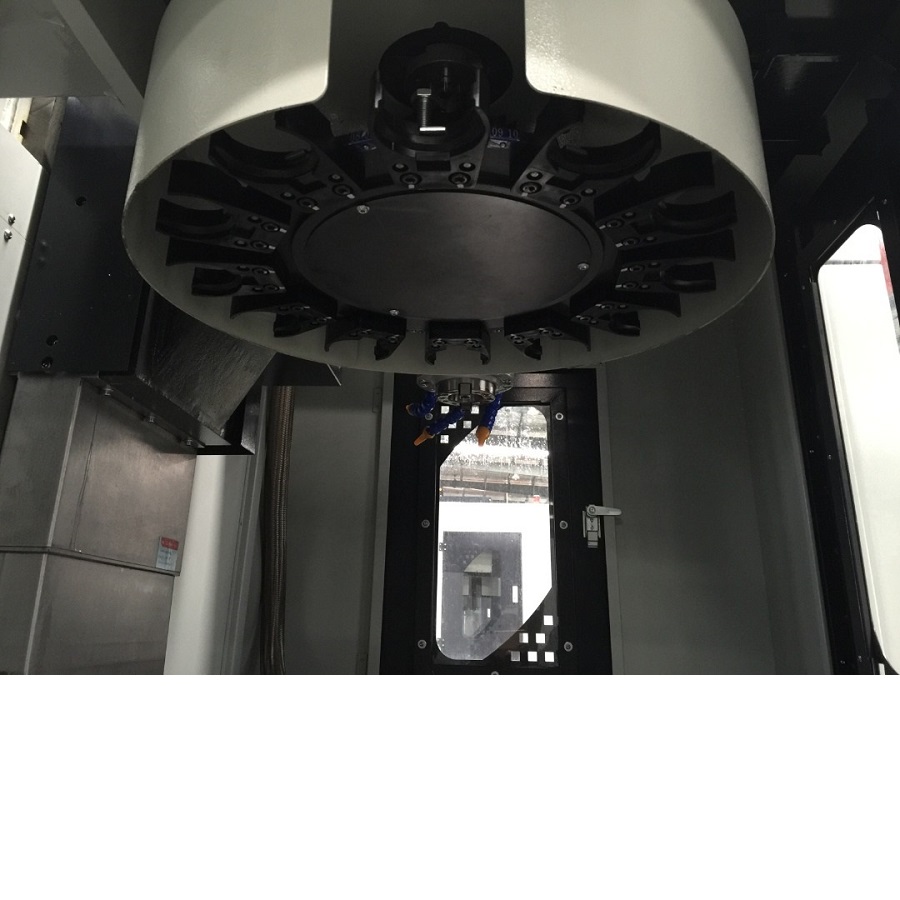

Key features include:

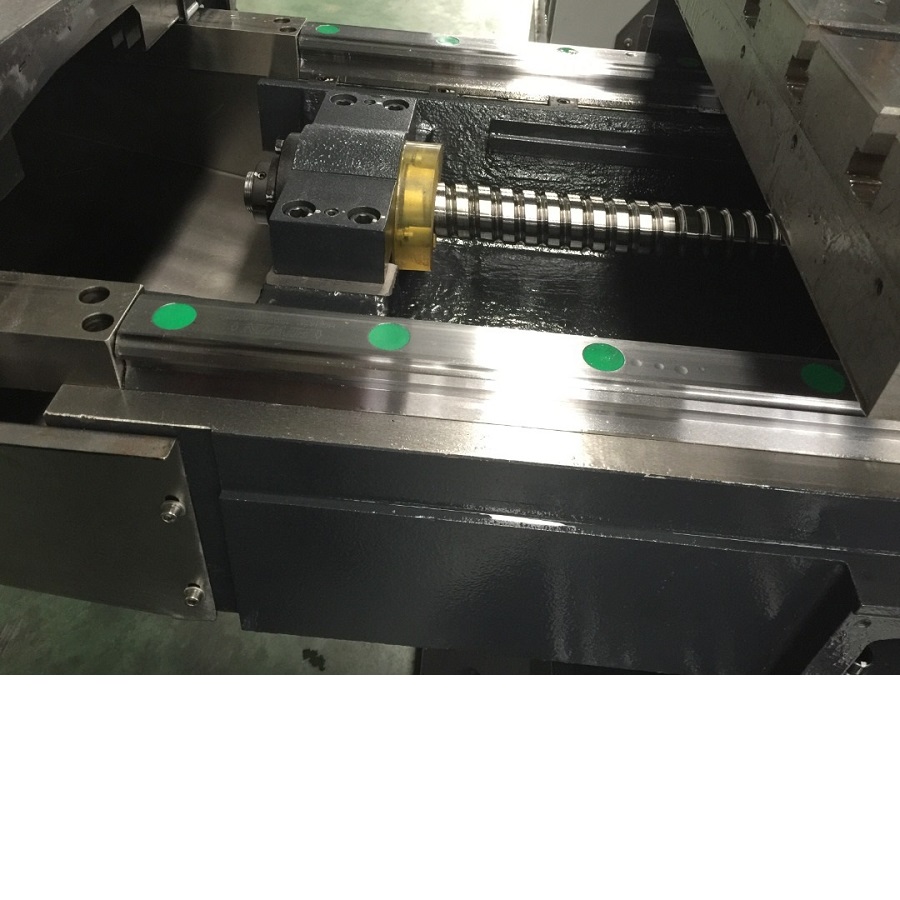

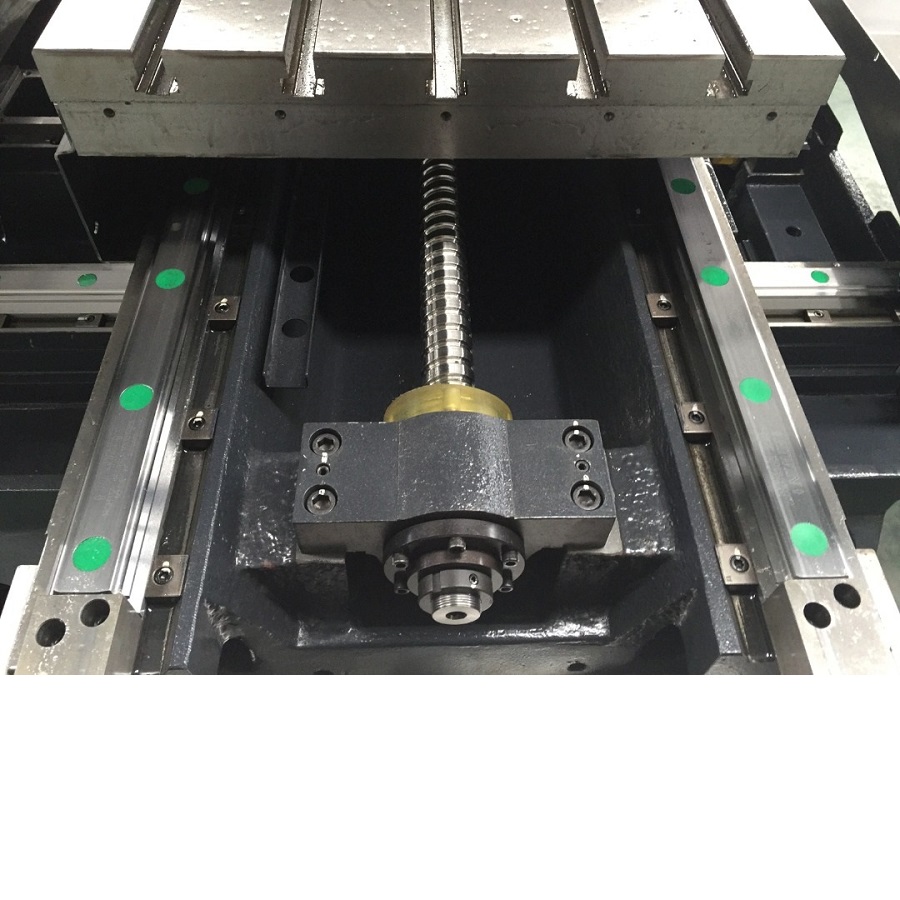

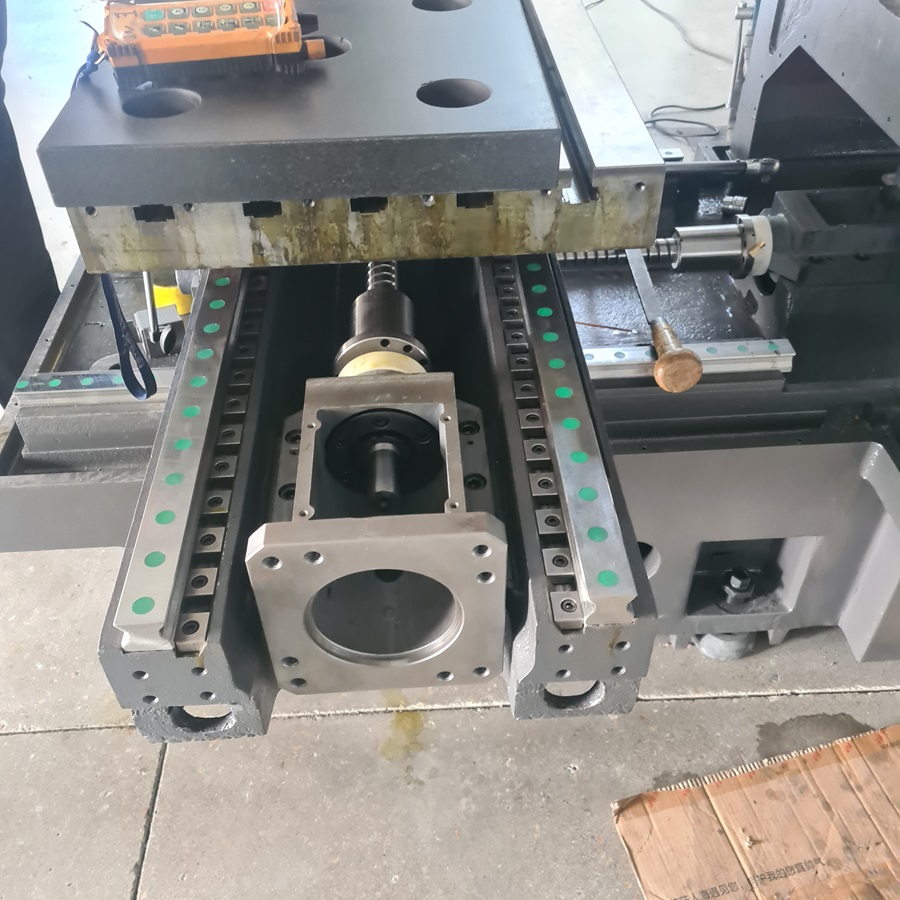

- HiWin linear rails (Taiwan) for smooth, precise movement

- SKF bearings (Japan) for durability and long-term accuracy

- A broad selection of models and configurations tailored to your specific application

All our machines are fully CE and CA marked, meeting the highest standards for safety, compliance, and quality assurance.

Contact us today to find the right CNC machining centre for your operation.

Controls

Available with a choice of controls from Fanuc, Siemens, Heidenhain & Fagor. We can supply the machine to your requirements at a price that is very competitive.

Specifications

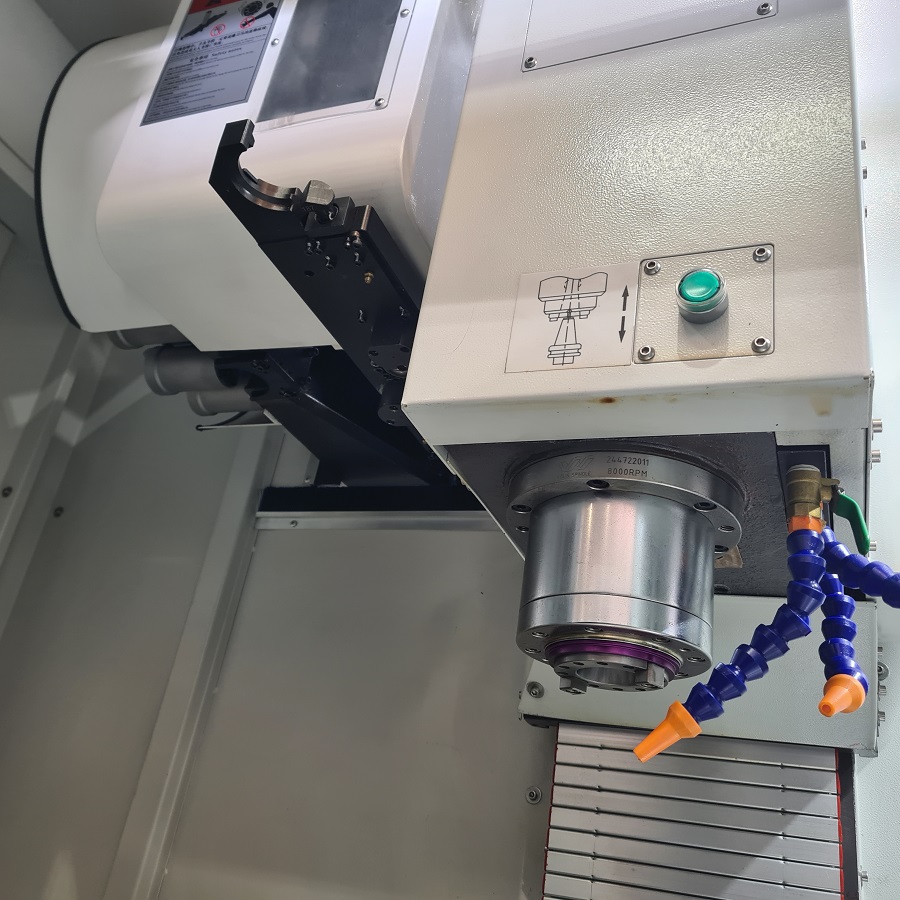

High-Speed Precision Engineering

All axes on our vertical CNC machining centres are powered by direct-drive AC servo motors, coupled with C3-grade precision ballscrews and linear rails, both from HiWin. This advanced configuration delivers:

- Exceptional speed performance

- Outstanding repeatability and accuracy — up to 0.005 mm

Each machine is fully enclosed, promoting a clean, safe working environment. The inclusion of both front and side access doors ensures easy loading, maintenance, and operator accessibility.

Gallery

Versatile, Clean, and Production-Ready

While our Vertical Machining Centres (VMCs) are primarily designed for high-efficiency production environments, many of our customers are using them in innovative ways — including for clean, organised one-off machining.

Thanks to their fully enclosed guarding, these machines significantly reduce mess and are easy to clean, helping maintain a tidy and safe workshop. This makes them ideal not just for production runs but also for individual components, where having tools pre-set allows parts to be produced faster and more accurately than manual methods.

To further enhance precision and productivity, we offer tool and workpiece probing systems from:

- Renishaw

- Heidenhain

- Or reliable generic alternatives

These probes simplify tool setting and in-process inspection, reducing setup times and ensuring consistently high-quality results.

Delivery and installation

Our delivery companies can deliver your machine and offload it with a variety of ways. Then either drive it in with a versa lift or skate it in to position. Then once its there our fully trained engineers will level and commission it. Once this is done we will train you in its operation.