Masterturn Flat Bed CNC Lathes.

Over 30 Years of Flat Bed CNC Lathe Expertise

For more than three decades, Semco has been supplying flat bed CNC lathes, building a wealth of experience in optimizing machine performance and efficiency. Our range includes everything from the compact Mini model (400 mm swing x 750 mm between centers) to heavy-duty machines with a swing of up to 2,100 mm and 8,000 mm between centers.

Get in touch today to speak with one of our engineers — we’re here to help you find the ideal solution for your application.

Design Features

Built for Performance and Ease of Use

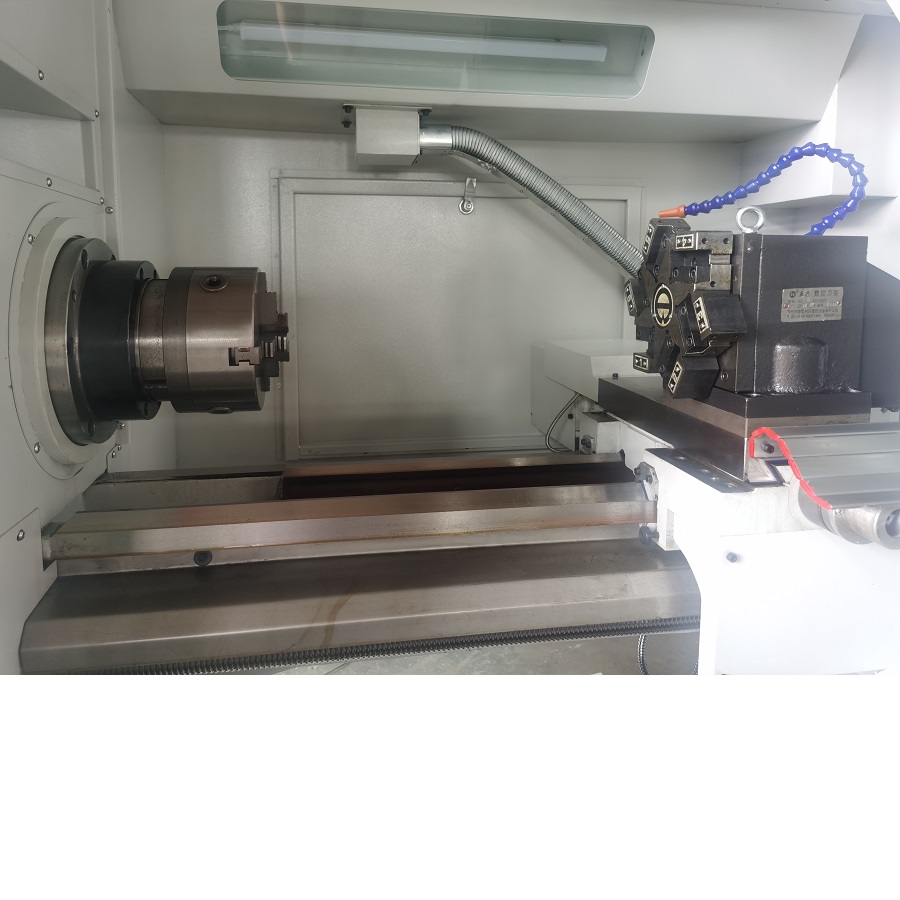

Our machines are equipped with high-quality components and thoughtful design features to ensure long-term reliability and operator convenience:

- NSK spindle and thrust bearings for smooth, precise operation

- Turcite B on hardened and ground slideways for reduced friction and extended machine life

- TBI ballscrews for accurate positioning and durability

- Automatic lubrication system to maintain optimal performance with minimal maintenance

- Portable handwheel (MPG) for precise manual control during setup and adjustment

- High-power LED lighting for clear visibility during machining

- Guard design with end access, making it easy to load larger workpieces or clean the machine

- Training videos covering both operation and programming to get you up to speed quickly

Options Include

Flexible Configurations to Suit Your Needs

Our CNC lathes can be tailored to match your specific requirements, with a wide range of control and configuration options:

- Choice of controls from Fanuc, Siemens, or Fagor

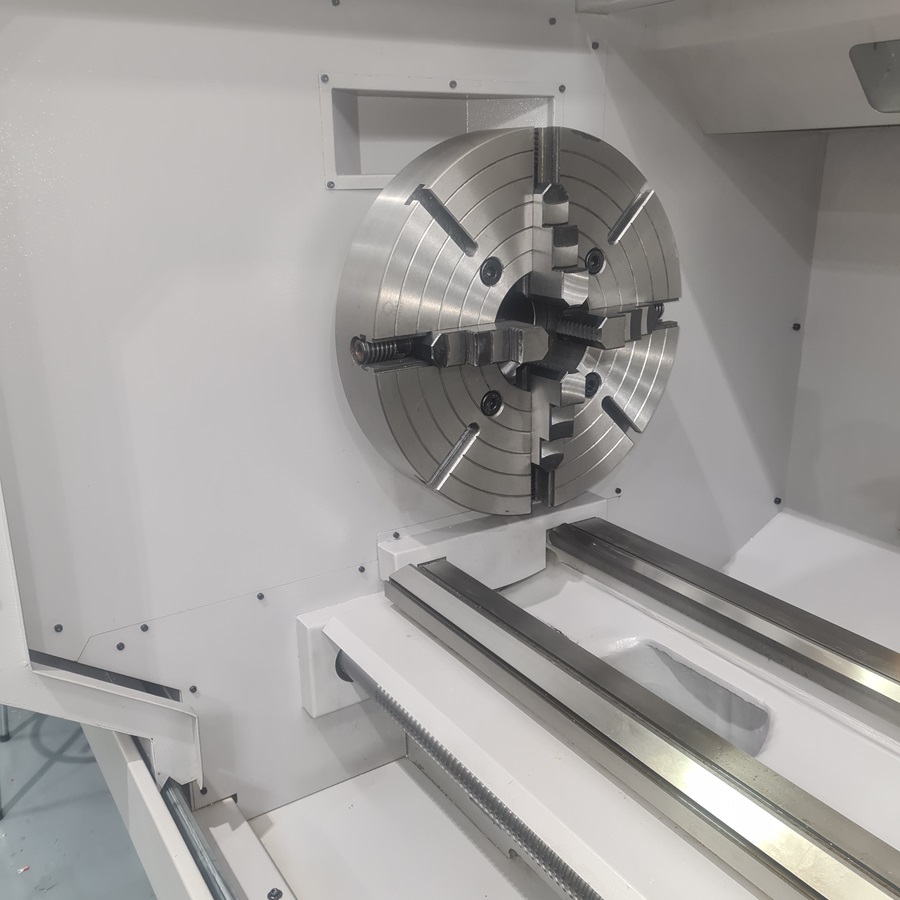

- Available with standard or power chucks and manual or hydraulic tailstocks

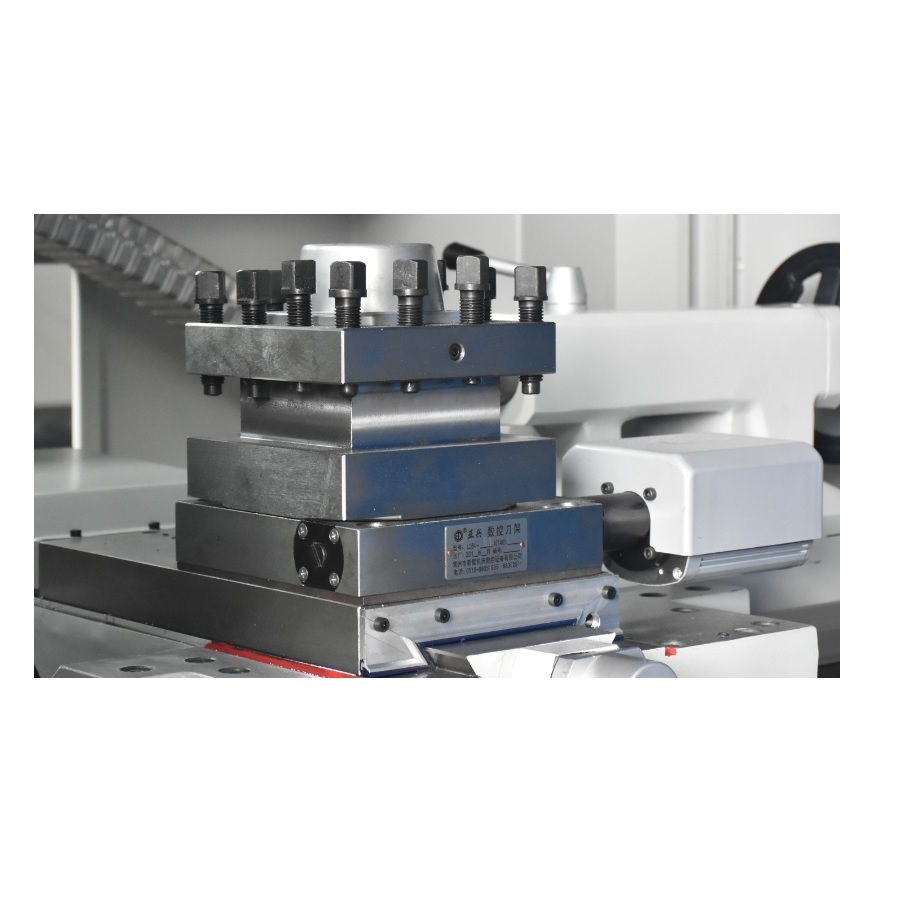

- Tooling options include 4-station automatic tool posts, or 6- and 8-station turrets

- Compatible with bar feeders for continuous production

- All machines are CE and CA marked, ensuring compliance with safety and quality standards

Specifications

Precision, Productivity, and Value

Our CNC lathes offer versatility for a wide range of applications — serving as both cost-effective production tools and precision machines for custom, one-off projects. With CNC control, entering a radius or diameter results in accurate, repeatable machining — far beyond what’s achievable on a manual lathe.

Our competitively priced smaller machines make it easy and affordable to produce ultra-precise components. For increased efficiency, adding a bar feeder can significantly streamline your production workflow.

Feel free to call or email us to discuss your requirements — our team is here to help you find the perfect solution.

Delivery, Installation & Training – We’ve Got You Covered

Our trusted delivery partners can transport and offload your machine using a variety of methods tailored to your site—whether that’s with a Versa-Lift or machine skates for precise positioning.

Once the machine is in place, our fully trained engineers will:

- Level and commission the machine

- Ensure everything is running correctly and safely

- Provide comprehensive training on operation and basic maintenance

From delivery to production, we support you every step of the way.

📞 Get in touch to arrange delivery and installation.