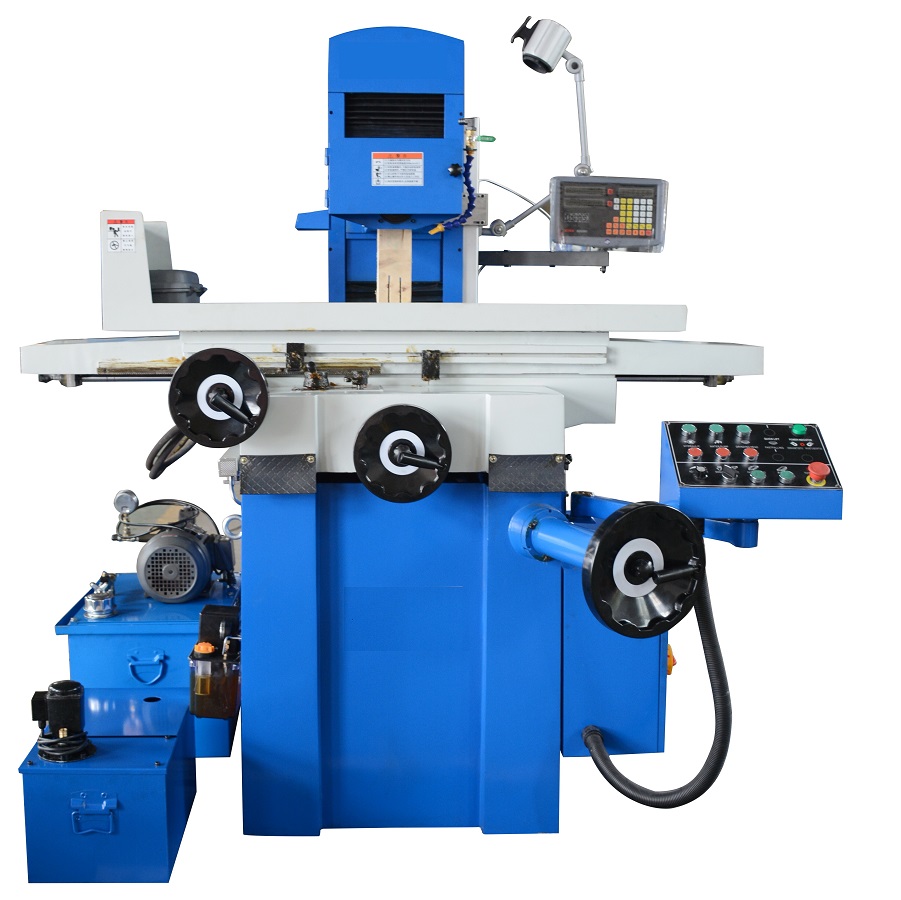

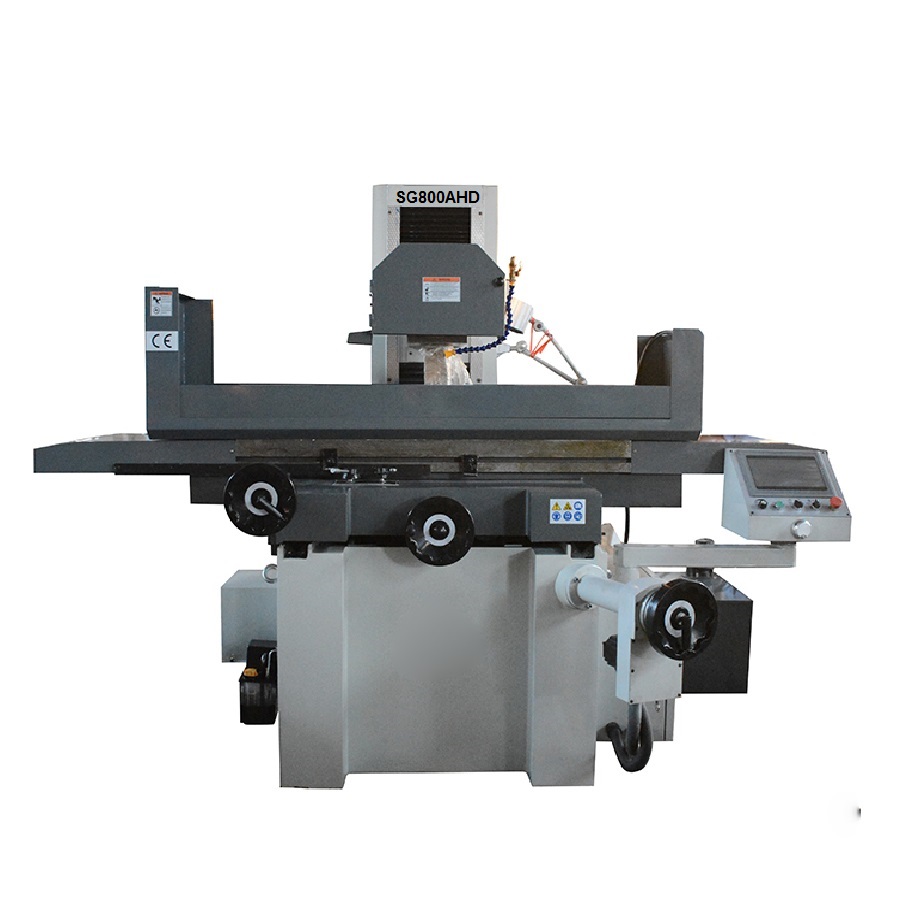

Semco Surface Grinding Machines

Semco Surface Grinding Machines — Precision Meets Value

Semco surface grinders provide a cost-effective solution for high-precision grinding, with electromagnetic chuck sizes ranging from 500 mm to 1,600 mm. Built for versatility and accuracy, these machines offer a range of downfeed options:

- Manual feed

- Step feed

- Fully automated PLC-controlled feed

Each machine includes:

- Digital Readouts (DRO) on both cross and vertical axes for precise measurements

- Electromagnetic chuck

- Wheel dresser

- Balancing stand and arbor

- Integrated coolant system

✔️ CE & CA Certified — ensuring safety and compliance

📞 Contact us today to find the perfect grinding solution for your application.

Surface Grinder Machines

When Precision Matters — Choose a Surface Grinder

For applications where flatness, smoothness, and accuracy are critical, a surface grinder is essential. These machines are widely used in tool rooms and precision engineering workshops, where building tools and components on perfectly flat surfaces is a must.

Whether you’re producing dies, fixtures, or high-tolerance components, surface grinding delivers the precision finish that other methods simply can’t match.

📩 Get in touch to find the right surface grinder for your needs.

Available with a range of sizes and options ready for your workshop.

Specifications

Options

With Full coolant system with paper filtration, magnetic filtration, overhead wheel dresser.

Why Choose Surface Grinding?

When a superior surface finish and higher accuracy than milling is required, surface grinding is the solution. It’s especially effective for working with hardened materials and tool steels such as D2, where milling may struggle or cause tool wear.

Surface grinders can also:

- Form grinding wheels to create grooves, channels, and intricate shapes in hard metals

- Deliver high precision finishes for toolmaking and die work

- Handle complex jobs with ease and repeatable accuracy

At Semco, we offer a comprehensive range of surface grinding machines to suit every application and budget.

📞 Contact us today to find the perfect model for your workshop.

Delivery, Installation & Training – We’ve Got You Covered

Our trusted delivery partners can transport and offload your machine using a variety of methods tailored to your site—whether that’s with a Versa-Lift or machine skates for precise positioning.

Once the machine is in place, our fully trained engineers will:

- Level and commission the machine

- Ensure everything is running correctly and safely

- Provide comprehensive training on operation and basic maintenance

From delivery to production, we support you every step of the way.

📞 Get in touch to arrange delivery and installation.