KEARNS HORIZONTAL BORERS

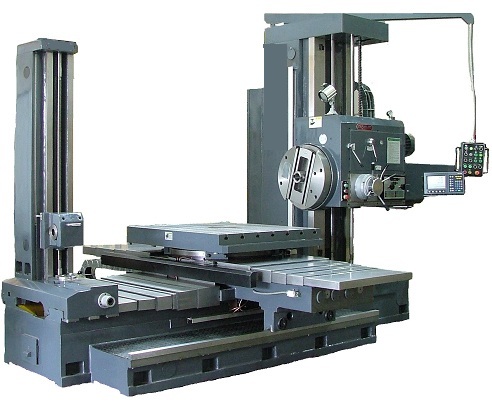

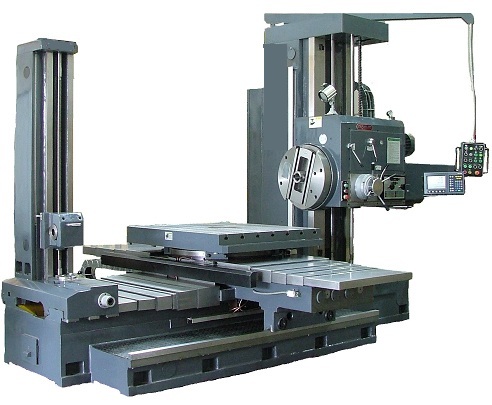

Kearns Horizontal Borer – Precision and Versatility in One Setup

The KEARNS Horizontal Borer is an exceptionally versatile machine, designed to allow precision machining of all four sides of a workpiece in a single setup. Once the first side is complete, the rotating table can be repositioned manually to preset angles using a visual positioning eye, making it easy to machine each subsequent side with accuracy and repeatability.

Whether you’re boring precision holes or require the capabilities of a large-format milling machine, these machines offer a powerful, adaptable solution.

Built for performance and longevity, each machine features:

- Boxway slides for smooth, high-precision motion.

- SKF bearings (Japan) for long-lasting reliability.

- Full CE and CA certification for compliance with international standards.

- 600mm Dia Boring head with cross feed for facing.

- Powered rotating table with high precision setting on a magic eye.

- Optional tail stock for line boring.

- 3 Axis Newall DP700 DRO for Accuracy & reliability.

With decades of production expertise, Semco is proud to support our customers with in-depth knowledge and reliable solutions. Contact us today to find out how this machine can fit into your workflow.

Specifications

Control.

All axes on the Kearns Horizontal Borer are driven by either the gearbox to give a wide range of feeds & speeds or a rapid travers motor to give better speed when moving around. Also all the axis can be hand feed to find high accuracy positions.

The quill can be used like a drill pulling the hand wheel out to gain feed which can be set to a depth.

Available with morse taper, BT50 with power drawbar spindle types.

Excellent for milling, drilling, boring, line boring & facing. A must in every machine shop.

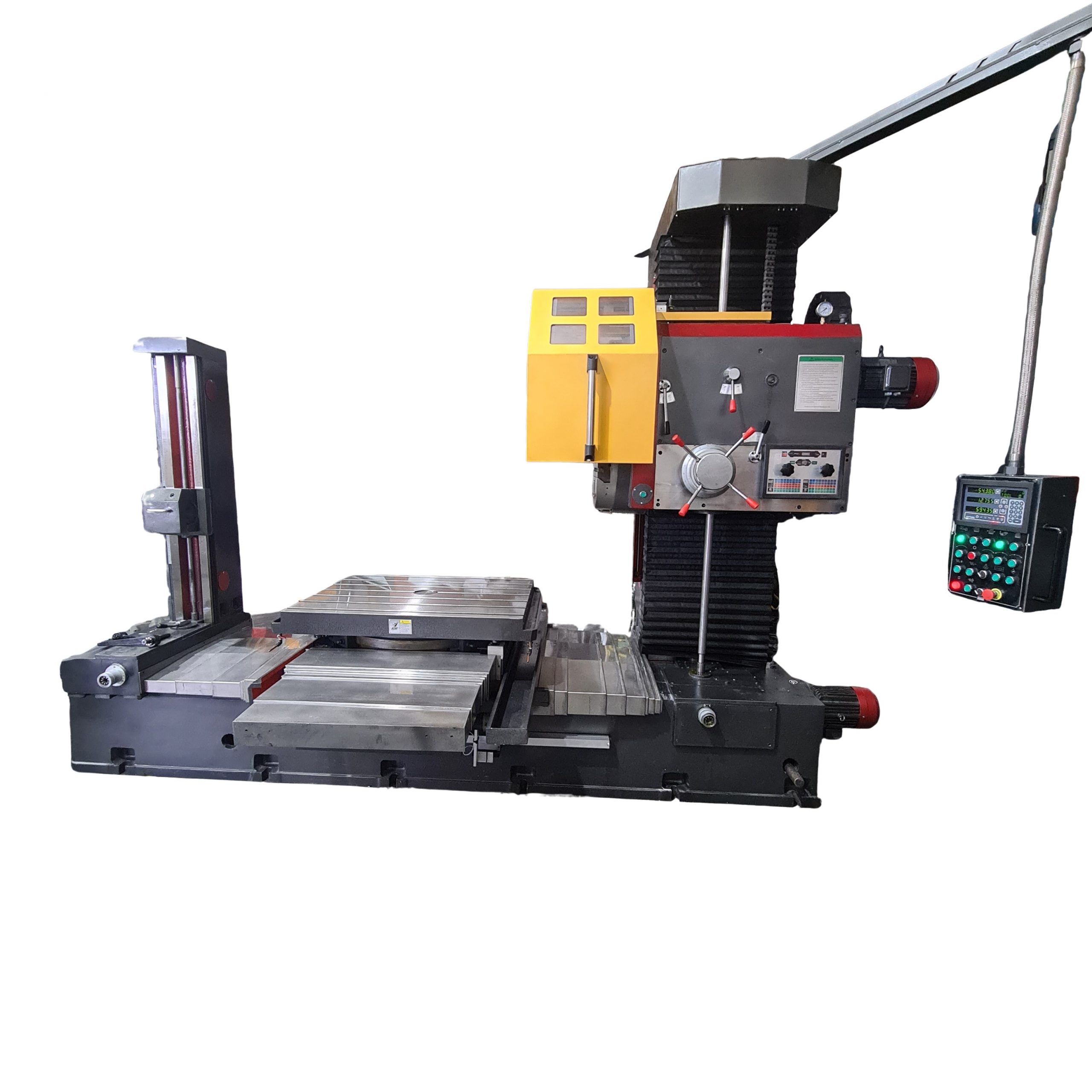

Gallery

Machine Production

Built to the Highest Standards

Kearns borers are manufactured in modern, state-of-the-art facilities, ensuring high levels of precision, consistency, and reliability. Every component is carefully selected to meet stringent quality standards:

- Electrical components from trusted names like Schneider and ABB

- Bearings sourced exclusively from leading Japanese manufacturers

This commitment to quality materials and controlled production environments results in machines that are built to perform — and built to last.

Delivery, Installation & Training – We’ve Got You Covered

Our trusted delivery partners can transport and offload your machine using a variety of methods tailored to your site—whether that’s with a Versa-Lift or machine skates for precise positioning.

Once the machine is in place, our fully trained engineers will:

- Level and commission the machine

- Ensure everything is running correctly and safely

- Provide comprehensive training on operation and basic maintenance

From delivery to production, we support you every step of the way.

📞 Get in touch to arrange delivery and installation.